Mold Lifting & Rigging Hardware

Looking for safer and more reliable safety solutions? DME has a variety of effiecient mold lifting hardware. Featuring products from American Drill Bushings, CodiPro, Jergens and more.

NEW – YOKE Yellow Points

Featuring

Hoist Rings

Chain Lifting Slings

New Hardware Solutions

Certified to highest safety ratings, hoist rings from DME fit your needs.

Lifting Best Practices

Make sure you’re using your eyebolts and hoists rings the proprer way for maximum safety.

Purchase on DME eStore

Superior Quality Lifting Hardware

Engineered for Safety

At DME safety come first. This philosophy has driven us to offer a collection of Mold Lifting and Rigging hardware that has been certified and proof tested. We stand behind these products and are confident they are the highest quality in the industry. Keep your most valuable assets, your employees and materials safe by using DME lifting hardware.

Safe Material Handling – Lifting With Standard Eyebolts

Selecting the correct bolt for each lift is critical in many ways.

Confirm the eye bolt is approved for the weight to be lifted, the rating should be forged or stamped on the eye bolt. Some eye bolts only have thread size visible and Not the maximum approved WLL.

- Use plain/regular eye bolts (non-shoulder) or ring bolts for vertical loading only. Angle loading on non-shoulder bolts will bend or break them.

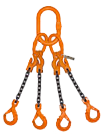

- Use shoulder eye bolts for vertical or angle loading (see the image below). Be aware that lifting eye bolts at an angle dramatically reduces the WLL (Working Load Limit).

- Always follow the manufacturer’s recommended method for angle loading.

Incorrect use of eye bolts:

Image 1 (shown below) demonstrate eyebolts will not rotate to the load causing extra load on the chain, the eyebolt and on the threads of the object being lifted.

Image 2 (shown below) shows the wrong eyebolt was chosen for the application because it could not be bottomed out on the object being lifted. The result causes the eyebolt to bend and could possibly brake at a much lower WLL than advised on the eyebolt.

Image 1

Image 2

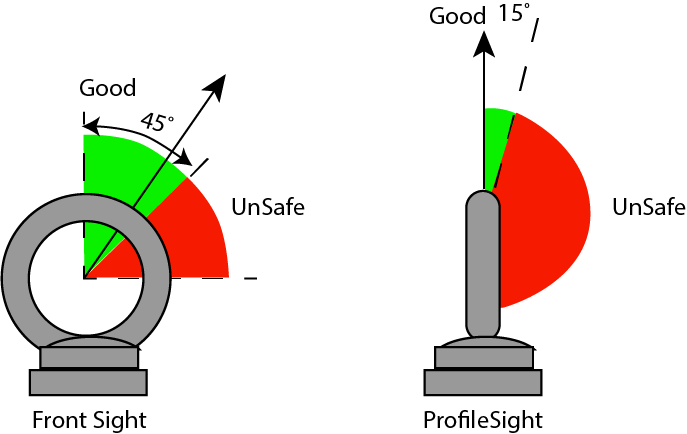

How should eye bolts be used/installed safely?

- Orient the eye bolt in line with the slings. If the load rolls when lifted and applied sideways, the eye bolt may bend.

- Ensure the eye bolt firmly contacts the surface if there are any gaps add washers between the shoulder and the load surface to ensure 360 contact. Make sure to properly torque the eye bolt and nut for through hole applications.

- The threads of the eye bolt must engage at least 90% in a receiving hole when using shims or washers.

- Only one sling leg should be attached to each eye bolt.

- Inspect and clean the eye bolt threads and the hole threads. Check for bends, cracks, debris, or worn threads.

- Screw the eye bolt all the way down and properly seat flush with the lift object.

For tapped holes ensure threaded portion of the eye bolt has a minimum depth of one-and-a-half times the bolt diameter.- Use a either a swivel eye bolt or hoist ring for angled lifts. The hoist ring will adjust to any sling angle each ring pivots 180 degrees and will swivel 360 degrees.

Tips for Safe Installation

Swivel Eyebolt in Use

What should you avoid when using eye bolts?

- Never use a single eye bolt to lift a load that is free to rotate.

- Never use eye bolts that have worn threads or other flaws.

- Never insert the point of a hook in an eye bolt, always use a shackle .

- Never use a shackle that is capable of lifting more than the eye bolt.

- Never run a sling through a pair of eye bolts this will reduce the effective angle of lift and will put more strain on the rigging.

- Never force the slings through eye bolts. This force may alter the load and the angle of loading ratings.

- Never use eye bolts that have been altered by grinding, machined or stamped.

- Never use bars, grips or wrenches to tighten eye bolts.

- Never paint an eye bolt this could cover up cracks and or flaws

- Never force hooks or other fittings into the eye they must fit freely and should be rated the same WLL as the eye bolt.

- Never shock load eye bolts as this could cause the eye bolt to snap.

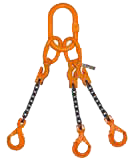

Chain Lifting Slings

DME Chain Slings offer versatility and security in a variety of configurations… always Tested and CE certified. Combine with DME’s other CE certified products for all your lifting needs.

- Sling Hooks & Self Locking Hooks available

- Grade 100 chain slings tagged with sling type, grade, size and working load limit

- Tested and CE certified before shipment

Single Leg Chain Sling with Adjuster & Hooks

Double Leg Chain Sling with Adjuster & Hooks

Triple Leg Chain Sling with Adjuster & Hooks